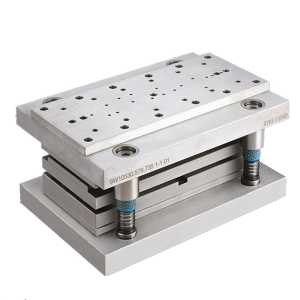

Precision Yas Txhaj Molding

Txawm hais tias cov qauv ntawm cov pwm tuaj yeem sib txawv vim muaj ntau yam thiab kev ua tau zoo ntawm cov yas, cov duab thiab cov qauv ntawm cov khoom yas, thiab hom kev txhaj tshuaj tshuab, cov qauv tsim yog tib yam.Cov pwm yog tsim los ntawm cov txheej txheem pouring, kev tswj qhov kub thiab txias, tsim cov khoom thiab cov khoom siv.Ntawm lawv, lub rooj vag kaw lus thiab cov molding qhov chaw yog cov khoom sib txuas ncaj qha nrog cov yas, thiab hloov nrog cov yas thiab cov khoom.Lawv yog cov feem ntau nyuaj thiab hloov tau qhov chaw nyob rau hauv pwm, thiab yuav tsum tau lub siab tshaj plaws ua tiav thiab precision.

| Khoom npe: | Qauv |

| Lub tuam txhab muaj zog: | 1, Pab neeg ua haujlwm tau zoo nrog ntau xyoo kev paub |

| 2, Kev xa khoom raws sijhawm | |

| 3, Cov khoom siv zoo heev | |

| 4, Siab zoo thiab tus nqi sib tw | |

| Khoom siv: | ABS, POM, PP, PU, PC, PA66, PMMA, PVC, PVE, Aluminium, Hlau |

| Xim | Txhua xim, raws li cov neeg siv khoom xav tau. |

| Kev kho deg: | lub teeb xim, dumb xim, roj hmab roj, pearlescent xim, Silk-printing, anodize, chrome plating |

| Cov ntaub ntawv tawm tswv yim: | Pro/engineer, Solidworks, UG, Auto cad |

| Lub sijhawm ua haujlwm | 25-50 hnub raws li cov khoom sib txawv |

| Kev pabcuam | 1, kev lag luam tsim |

| 2, Brass / Aluminium qhov chaw machining | |

| 3, Rov qab engineering | |

| 4, Txhaj tshuaj molding | |

| 5, ceev silicone pwm thiab nqus casting | |

| 6, CNC qauv tsim | |

| Kev lag luam teb | 1. Kev Tsim Kho Kev Ua Haujlwm (ODM & OEM project) rau Kev Tsim Kho Kev Lag Luam, ME thiab Kev Tsim Kho Kho vajtse, txheej txheem txheej txheem thiab ntau lawm. |

| 2. Magnesium- Alloy & Aluminium-Alloy ib feem raug | |

| 3. txheej txheem txheej txheem (Plastic pwm, Stamp-Die, Tuag-Casting thiab Sand Casting) | |

| 4. Hlau machining qhov chaw tsim khoom | |

| 5. Ceev Prototyping | |

| 6. Tsawg ntim ntau lawm los ntawm CNC, RTV, thiab Fast-pwm thiab lwm yam. |